PU leather for vehicle seats

Contact:

TEL:

E-mail:

Product Application

Product Application

Product Description

Excellent Basic Performance

Meets requirements for flame retardant, light resistance, heat resistance, odor, and atomization for vehicle use.

Can be designed in combination with material standards from various car manufacturers.

High Durability

Weather resistance tests show no surface cracking, ensuring durability of over 10 years.

Good Appearance and Coating

Full hand feel, good texture, excellent coating properties, and aesthetically pleasing molding. Designed with natural and variable surface colors and gloss, including lychee, nappa, and geometric patterns with varied textures.

High Abrasion Resistance

Wear resistance can reach 20,000 cycles. Complies with entry and exit tests from multiple car manufacturers.

Environmentally Friendly

Low solvent and solvent-free formula combinations, low volatility, low odor, in compliance with national environmental protection policies.

Product Use

Suitable for various automotive interiors and motorcycle seat cushions. Widely used in dozens of car manufacturers across European, American, Japanese, and domestic brands.

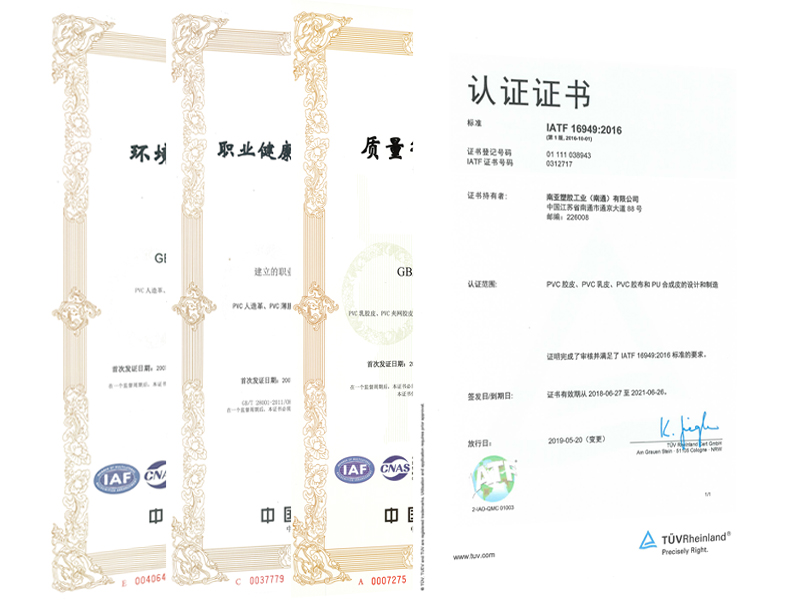

Product Certificates / Product Catalog

ISO14001, OHSAS18001, ISO9001, IATF16949

Product Description

Excellent Basic Performance

Meets requirements for flame retardant, light resistance, heat resistance, odor, and atomization for vehicle use.

Can be designed in combination with material standards from various car manufacturers.

High Hydrolysis Resistance

Weather resistance tests show no surface cracking, ensuring durability of over 10 years.

Good Flexural Resistance

No cracks after 300,000 cycles at room temperature and 50,000 cycles at -30°C.

High Abrasion Resistance

Wear resistance can reach 20,000 cycles.

Environmentally Friendly

Low solvent and solvent-free formula combinations. Complies with national environmental protection policies.

Product Use

Suitable for various automotive interiors and motorcycle seat cushions. Widely used in dozens of car manufacturers across European, American, Japanese, and domestic brands.

Product Certificates / Product Catalog

ISO14001, OHSAS18001, ISO9001, IATF16949

Product Model

Product Model

Product

Specifications

Characteristics

Uses

Microfiber PU

0.8-1.3mm

Can be perforated to replace genuine leather, with a hand feel close to genuine leather. Mechanical properties superior to genuine leather, meeting automotive standards.

Perforable PU

1.0-1.2mm

Solid hand feel, good touch, high abrasion resistance, can be perforated, more suitable for main materials of seats.

Non-perforable PU

0.8-1.2mm

Solid hand feel, good touch, high abrasion resistance, excellent coating properties, suitable for non-perforated materials such as headrests.

Key words:

High wear-resistant PU

high hydrolysis-resistant PU

for seating use

can be perforated.

NANYA PLASTIC INDUSTRY (NANTONG) CO., LTD

South Asia

Synthetic leather factory business office contact: Mr. Shen Mr. Wu

TEL:13646278635 13320894516

E-mail:keyiwu@nypc.com.cn

Copyrights©2024 NANYA PLASTIC INDUSTRY (NANTONG) CO., LTD